The construction industry is prone to several potentially catastrophic accidents. If you keep accident rates low, you can prevent delays and unnecessary costs for workers injured at work.

Construction Site Safety Tips

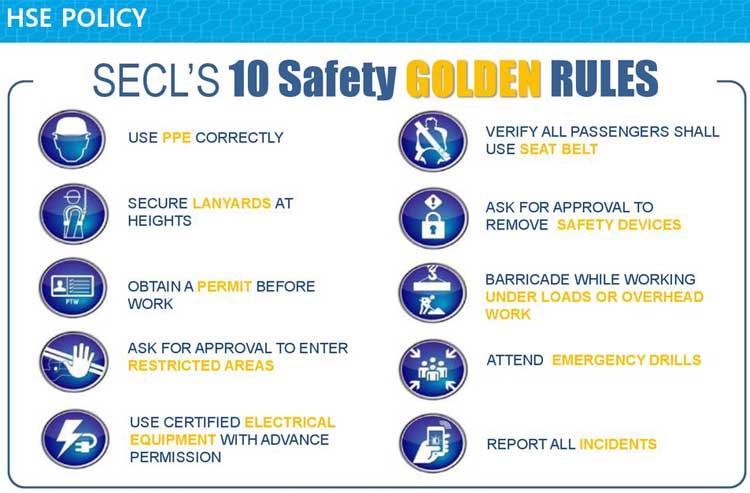

You can improve your HSE performance by following these ten construction safety tips.

1. Safety Culture

As a result of demonstrating leadership, firms help employees understand the importance of safety and why they should get driven to support it. A successful safety culture starts at the top. HSE success gets strongly correlated with strong leadership and strong management commitment.

Employee attitudes and behaviour towards construction site health and safety get substantially influenced when strong leaders lead and explain by example what HSE acts are acknowledged, tolerated, and punished.

2. Management System

Instead of depending on numerous systems, all safety program components should get integrated into a single management system controlled by line management. It provides a structured management strategy to efficiently manage HSE processes through an integrated HSE management system.

For construction sites, KPIs and metrics can help predict and achieve desired results, prevent problems, and solve them before they arise.

3. Safety in Business Processes

A construction site’s HSE processes will stay robust regardless of organizational changes if safety gets made a core value instead of just a priority. Priorities alter in most organizations. Because safety, health, and the environment are fundamental values, they have not altered.

4. Proper HSE Program Management

Workplace safety, health, and the climate already get integrated into the business world. In the same way that every other business gets managed as as safety too. Safety requires the same management skill and effort as quality, cost, scheduling, production, and many more.

5. Rationalization

Employees are not encouraged to adopt a safety culture by scaring them or playing on the emotional components of workplace illnesses and injuries. A method based on rationality and discipline is the way to go when trying to understand why safety risks and problems develop.

Whenever construction workers have a better understanding of safety issues, their view on worksite safety expands. The reasons these safety and HSE measures get implemented become more apparent.

6. Discipline

Another significant indication of safety is a company’s commitment to disciplining employees who violate safety rules, which is frequently overlooked by employees, according to a recent study.

For safety violations, most businesses don’t reprimand their workers. It’s because of an injury if they’re out of commission. Something happened that showed infractions of safety standards, but it’s not a punishment.

7. Cleanliness

It’s easy to recognize the dangers of building sites. As a leading indicator, housekeeping is one of the finest indicators of safety. An untidy construction site can lead to preventable accidents. Organize frequent checks of potential hazards, such as cords twisted, dirty flooring, and untidy tools.

8. Safety Meetings

There are various ways to engage workers, but monthly safety meetings are the most effective way to do so. A good safety culture can get achieved by implementing a few vital elements. It’s a bit dorky, but it’s never a bad idea to be on the safe side of things.

Routine meetings allow construction site safety standards and preventive measures to be reviewed by management and workers in a collaborative setting. When something unexpected happens on-site, everyone knows what to do.

9. Open Communication

When managers provide regular updates and encourage open dialogues, employees better grasp the company’s general goals and their role in helping to attain these objectives.

The ease with which employees can discuss health, safety, and environmental concerns on the building site directly results from maintaining active and open discussions. As a result, workers are more likely to report possible problems to management as soon as they occur.

10. Accountability

Through frequent and ongoing communication of core values, engagement in incident investigations, and participation in audit teams, companies may engage workers in safety processes. They will take ownership of their obligations and accept responsibility for their mistakes if they witness top management who talks the walk when developing and following HSE processes.

Conclusion

To sum it all up, we can say that for your employees to be safe at work, it’s important to invest in security programs and provide them with the required training on the equipment and processes used in the workplace and follow the above construction safety tips.